Diesel Emission Controls

Power systems are subject to increasingly stringent regulations regarding allowable emissions, and current emissions controls are expensive to implement. Plasma reformers are proven to reduce several emissions in a single application (including NOx, HC, CO and PM).

H2 Emission Control Technologies

Syngas Enhanced Combustion

Fuel Cells

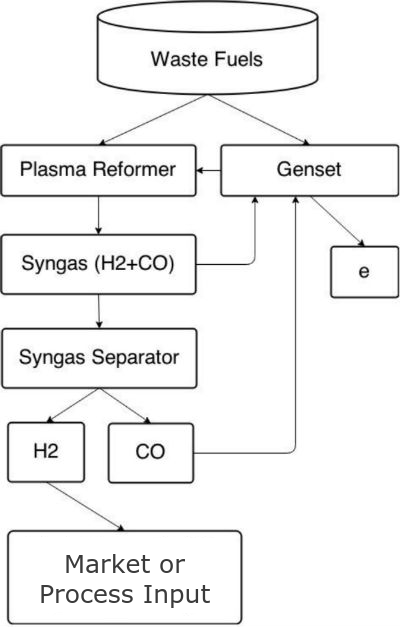

Purity of input fuel for fuel cells is key and your feedstock can be cleaned into syngas by using a plasma reformer. Fuel cells can be limited depending on the available fuels in the application of the technology. A plasma reformer is perfect for fuel cells as it cleans input fuels into pure syngas before entering the fuel cell.

Fischer-Tropsch

Fischer-Tropsch converts syngas into liquid fuels and was invented in Germany in 1925 and has constantly seen improvement since the first uses in that day. While gasification units typically power the systems today, plasma reformers are a great fit towards a more modular and possibly even semi-mobile state to produce fuel where and when needed.