Unlock cleaner energy with plasma reformers that convert waste gases and primary fuels into syngas (H2 + CO), slashing emissions like HC, CO, PM, and NOx while boosting ROI for industrial systems.

Plasma reformers integrate seamlessly into stationary power, fuel cells, and Fischer-Tropsch processes, enabling modular fuel production anywhere—meeting even the toughest regulations affordably.

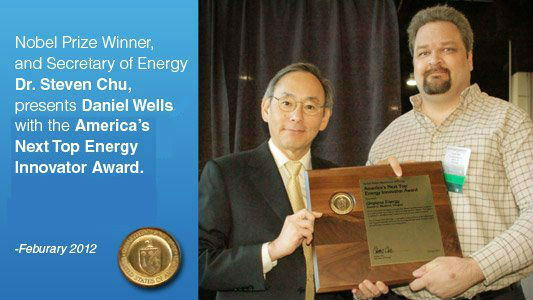

Daniel Wells, ex-Umpqua Energy CEO and DOE "America's Next Top Energy Innovator" awardee, leads our mission to embed plasma solutions in your operations.

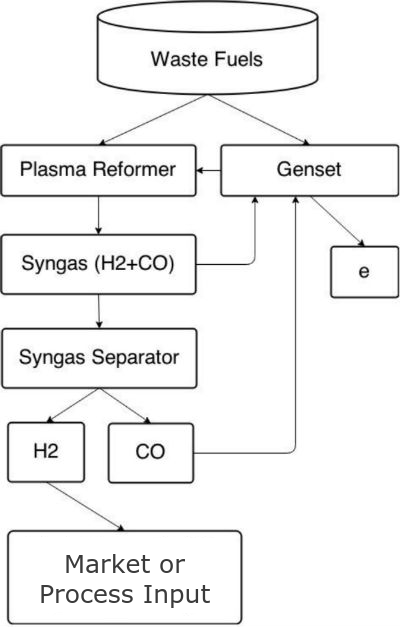

Partner With UsData centers are deploying vast arrays of natural gas-powered gensets—such as fleets delivering gigawatts of prime and backup power—to bypass grid bottlenecks and fuel AI growth. Plasma reformers integrate seamlessly, converting methane-rich feeds (from flares or pipelines) into syngas for ultra-clean combustion, slashing emissions and unlocking energy from natural gas. Build one large plasma reformer for your entire data center or build for each of your gensets, the choice is up to you.

Syngas blended with natural gas in combustion engines reduces emissions by enhancing flame speed and promoting more complete fuel oxidation, primarily due to its hydrogen content.

The high reactivity of syngas (H₂ and CO) accelerates laminar flame speeds in natural gas mixtures, minimizing unburned HC formation under lean or stoichiometric conditions in spark-ignition engines. Studies confirm linear HC reductions with increasing syngas ratios, as H₂ boosts OH radical concentrations for better oxidation.

Live testing on a diesel pickup truck and a natural gas genset using a gas analyzer and a dyno.

| Aspect | Plasma Reformers |

|---|---|

| HC | Reduction up to 95% |

| CO | Reduction up to 98% |

| PM | Visible (nearly complete) reduction in smoke on a diesel truck |

| NOx | Slight increase due to temps, mitigate with SCR or DeNOx Catalyst |

| HP | Increase up to 12% based on engine load per dyno on a diesel truck |

Plasma Reformers and hydrogen blending serve distinct purposes in enhancing natural gas engine performance for data centers, though both aim to cut emissions like HC, CO, PM and NOx.

Plasma Reformers use plasma technology to convert natural gas into syngas (H2 + CO) on-demand within the fuel system, injecting this hydrogen-rich mix directly into engines for cleaner, more efficient combustion. Hydrogen blending, by contrast, mixes pre-produced pure hydrogen (typically 5-20% by volume) into natural gas pipelines or fuel streams upstream. Plasma Reformers offer independence from hydrogen supply chains, ideal for remote or high-reliability data center generators amid grid constraints. Hydrogen blending suits larger pipeline-fed setups but faces regulatory hurdles on H2 injection limits (e.g., 20% max in some regions).

| Aspect | Plasma Reformers | Hydrogen Blending |

|---|---|---|

| Hydrogen Source | On-site reforming of ng or methane via plasma | External supply (e.g., electrolysis) |

| Infrastructure | Compact reformer unit per engine/site | Pipeline modifications, storage tanks |

| Emissions Impact | Reduces HC/CO via syngas; no H2 transport | Lowers NOx/HC; risks methane slip |

| Scalability | Modular for data centers, no grid tie | Network-dependent, blending limits |

| Cost | Higher upfront for plasma tech | Sourcing challenges + high cost electrolyzers |

| Tuning & ROI | Optimize for engine load & HP gains | General % range |

Power systems are subject to increasingly stringent regulations regarding allowable emissions, and current emissions controls are expensive to implement. Plasma reformers are proven to reduce several emissions in a single application (especially HC, CO and PM).

Purity of input fuel for fuel cells is key and your feedstock can be cleaned into syngas by using a plasma reformer. Fuel cells can be limited depending on the available fuels in the application of the technology. A plasma reformer is perfect for fuel cells as it cleans input fuels into pure syngas before entering the fuel cell.

Fischer-Tropsch converts syngas into liquid fuels and was invented in Germany in 1925 and has constantly seen improvement since the first uses in that day. While gasification units typically power the systems today, plasma reformers are a great fit towards a more modular and possibly even semi-mobile state to produce fuel where and when needed.

Plasma Reformers are poised to achieve the highest standards that regulators can enforce. The technology is so versatile that it is relevant to every combustion engine, fuel cell and Gas-to-Liquids technologies. There are boundless amounts of wasted fuels that can be converted to useable energy because of plasma reformers. As regulators raise the bar, industry will rely on plasma reformers to solve new challenges.

Daniel Wells (ex-CEO of Umpqua Energy) received International recognition after being awarded the "America's Next Top Energy Innovator" Award from the Department of Energy and by winning the CTSI Defense Energy Technology 2012 Challenge by developing an energy positive emission control system including HC, CO, PM and NOx reduction by using a plasma reformer.

Copyright Daniel Wells 2019-2026